High Pressure Water Spraying Technology

Working Principle

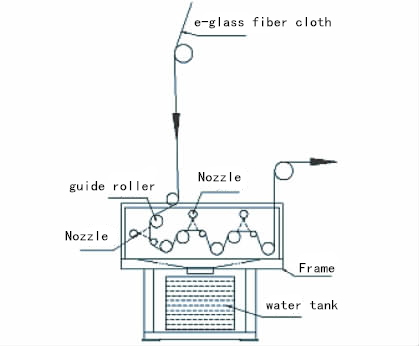

High-pressure water jet fiber technology works shown in Figure 2. e-glass fiber cloth through a number of guide rollers composed of the opening machine, through the high-pressure pump and nozzle, the high-pressure water (soft water) sprayed on the front and back of e-glass fiber cloth, there is a adjustable plate in the bottom , so that e-glass fiber cloth weft and warp yarn fibers can uniformly dispersed.

Figure 2 high-pressure water jet fiber works

Through the circulating pump, two filtration system, storage tank (plus pay), water tank to form a soft water circulation system. To ensure that the circulating soft water to achieve a dynamic balance, circulating water pump driven by the inverter motor. Work should always observe the two filter system pressure, once the filter bag, to clean up in time to prevent soft water overflow.

The selection of technical parameters

The open fiber effects of the e-glass fiber cloth depends on the high-pressure pump outlet pressure, nozzle type and nozzle-to-cloth distance. Different types of fiberglass fabrics, the choice of the parameters are also different. Usually the thinner the e-glass fiber cloth, the lower the pump pressure, the smaller the nozzle flow, the nozzle to the cloth spacing to be large, it is necessary to ensure adequate open fiber, but also can not produce water stains in the fabric.

Nozzle selection and distribution

Nozzle angle

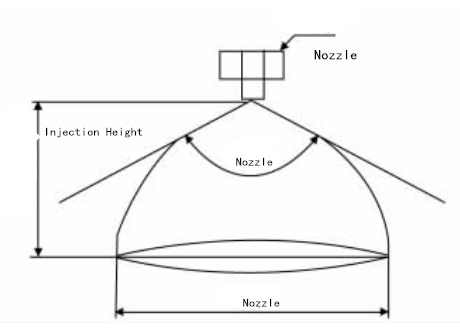

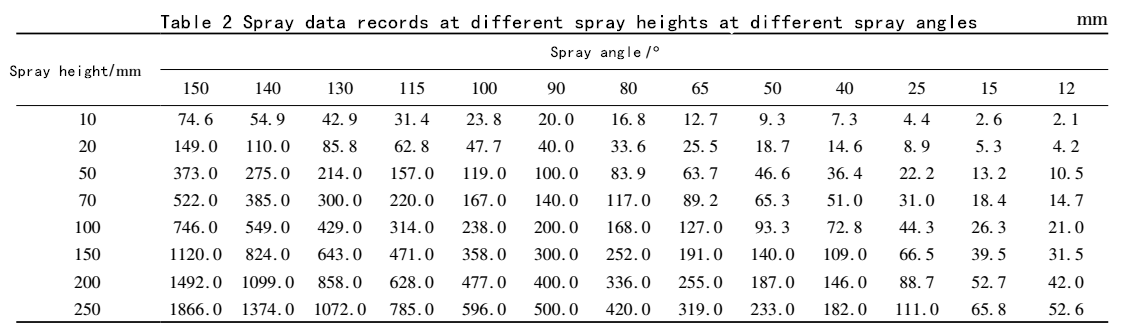

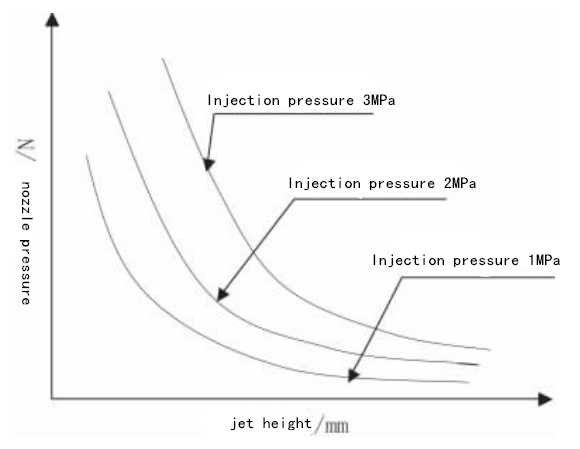

Nozzle angle and the jet height and the relationship between the spray shown in Figure 3 and Table 2.

Figure 3 The relationship between the nozzle angle or the jet height and the spray

Table 2 Spray data records at different spray heights at different spray angles

From Figure 3 and Table 2 we can see the relationship between the spray angle, jet height and the spray. Taking into account the need to open a larger jet force, the general choice of spray angle is 65 ° ~ 80 °, the spray height is range from 70 ~ 100 mm, spray overlap is range from 1/4 spray from the above data can be roughly determined between the nozzle distance.

Nozzle pressure

The relationship between the ejection force , nozzle pressure and ejection height is shown in Fig.4

As is clear from Fig. 4, the ejection force is inversely proportional to the ejection height and proportional to the nozzle pressure. After the test contrast, the nozzle pressure with 7628 cloth is 3 ~ 5 MPa , the nozzle pressure with the thinner fiberglass cloth is 1 ~ 3 MPa.

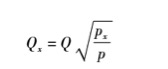

Nozzle flow

Nozzle manufacturers generally will provide nozzle flow and pressure table, if the selection of data beyond the scope of the table can be calculated using the following formula.

Figure 4, the relationship between injection pressure, jet force and jet height

Among them

Qx ——the selection of the nozzle flow,l/min;

px ——the pressure of the nozzle flow,MPa;

Q———the nozzle flow rates on the table,l/min;

p——the nozzle pressure on the table,MPa。

Usually a single nozzle flow rate is 200 ~ 300l / min of the e-glass fiber cloth with width 1270mm,In the high-pressure, the soft water in the nozzle with a high-speed flow, especially after the soft water recycling, which inevitably mixed with glass fiber impurities, so that the nozzle mouth wear increased, so the opening nozzle materials are creamic, its service life is 20 to 30 times than stainless steel .

Water spray open fiber results

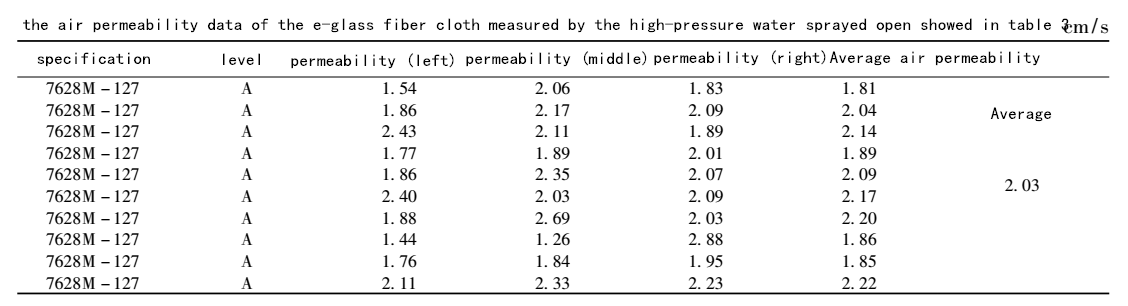

The air permeability data of the 7628 e-glass fiber cloth measured by the water spray open showed in Table 3

The air permeability data of the e-glass fiber cloth measured by the high-pressure water sprayed open showed in table 3