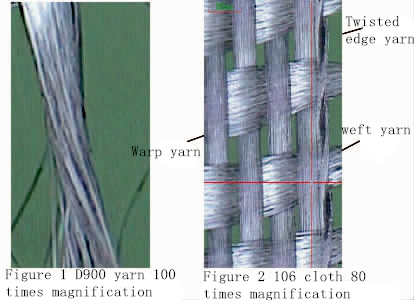

High-performance electronic fabrics need high-quality electronic yarn. Some important characteristics of electronic cloth is almost entirely dependent on warp and weft yarn, and the quality of warp and weft yarn is closely related to the twisting process.

The warp and weft yarn twisting process is completed in the high-speed first twist machine. In the process of drawing a single pool of raw silk for the warp and weft yarn, has been in line with the weaving of electronic cloth requirements, no further shares. The reason why through the twisting process, but to the original fiber in the twister on the hot air through the further drying, a small amount of twisting after winding into a suitable for warping, weaving production needs of the bottle-shaped tube. Twisting speed has been reduced from the original 40 twist / m, to the current 28 twist / m, is also to 20 twist / m development, Yarn volume also increased from the original 2Kg to the current 4-8Kg. This series of process improvement of electronic yarn is to ensure the further improvement of the quality of electronic cloth. The electronic cloth production process is as follows.

Raw fiberglass》Initial twist》Batch warping》shaft sizing》drawing》Air – jet looms》Inspection cloth 》Continuous heat treatment 》Batch heat treatment 》Surface chemical treatment》test.

Electronic fabric structure

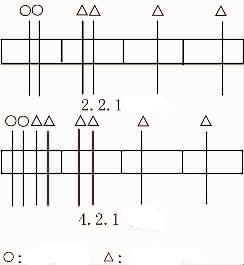

The arrangement of warp and weft yarns in the fabric and the state of joining with each other are called fabric structures. Fabric structure depends on the warp and weft yarn diameter, number of shares, twist, linear density, warp and weft density, fabric and fabric parameters and many other factors. Variations in these factors, as well as different combinations of each other, can constitute a number of structural properties of different glass fiber fabric to meet the needs of different uses.

The filament diameter of the electronic warp and weft yarns is 9 m or less, and there are four grades of 5 m, 6 m, 7 m and 9 m. In general, finer monofilaments can be made into finer yarns ,while finer yarns can be woven into thinner fabrics. And the same thickness of the cloth, such as the use of smaller diameter single warp and weft, the cloth’s softness, mechanical properties and durability are better. In addition, the original drawing coated fiberglass sizing, not only played at the time of drawing lubrication and cluster effect, but also improve the flexibility of the strand to a certain extent, abrasion resistance and resistance to bending performance. In particular, the current drawing infiltration agent, most manufacturers have adopted a modified starch infiltration agent, so that the original fiberglass textile performance has been significantly improved.

The fabric weave represents the weaving rule of warp and weft yarn. Industrial electronic fabrics are mainly plain, twill, satin and leno four organizations. Plain weave is the simplest and most commonly used fabric. Compared with twill and satin weave, weft and weft yarns in plain weave have the highest number of weave points and buckling numbers, and are close to each other. The fabric is relatively tight and flat and suitable for most electrical insulation and reinforcement materials. In general, plain weave are used in CCL with a variety of electronic fabrics .

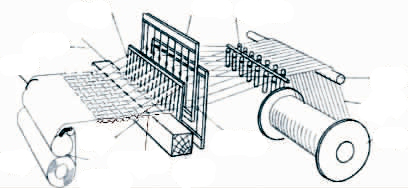

Technical Characteristics of Air – jet Looms

At present, the electronic cloth air-jet loom production. The current air-jet loom speed has reached 600 ~ 750r / min, which can produce a uniform tension, smooth cloth, no hair loss and high-quality electronic embryo and maintain a high weaving efficiency. The roll length of the electronic fabric is usually 2000 m / roll, up to 4000 m / roll. Specific technical characteristics are as follows.

Using electronic let-off, electronic coiling, to achieve positive sent by the coiling and stabilize warp tension

Using photoelectric double-weft can detect the lack of weft, weft release, but also beyond the detector weft So that reduce the zonal defects (for very little weft broken glass fiber fabric only need a weft)

Using electronic control weft storage device to stabilize the weft tension. The weft yarn discharged from the main nozzle is wefted by the auxiliary jetting force, and then is finally attracted by the terminal drawing nozzleso that reduce the weft and the weft untwisting defect

Using positioning parking, locating the effective control of driving and braking angle, and a shuttle, reversing and other functions, which effectively prevent the switch car’s dense road defects.

Using automatic pair shedding device and device for preventing the driving mark, So that the fabric weft defects greatly reduced

Electronic cloth post – processing

In order to further improve the physical and chemical properties of electronic cloth and its products processing performance, which need to post-processing electronic fabric. Including the heating, removal of raw silk in the drawing process of drawing the coating of infiltrating agent, as well as the yarn in the sizing process of coating the slurry, a surface layer of the fabric impregnated with coupling agent. This process is called thermal-chemical processing (“post-processing”). Electronic post-processing process, including continuous heat treatment, batch heat treatment and surface chemical treatment of three parts.

Continuous heat treatment

Continuous heat treatment, also known as pre-desizing. The continuous heat treatment of the gray fabric was performed on a continuous heat treatment unit (hereinafter referred to as KH unit). The core of the unit is a high temperature desizing furnace. To keep the continuous operation, the unit consists of several units, mainly for the cloth feeder, feeding and sending device, winding device. For the cloth machine with a roll for the cloth with a hot device, In order to change the volume in the continuous operation of cloth, feeding the fabric section and the feed section is configured with cloth storage device, The fabric is fixed on the cloth feeding machine, the cloth for feeding cloth is fed into the storage rack by the feeding roller, and the cloth drawn from the storage section of the feeding section enters the high-temperature desizing furnace through guide rollers. The fabric of organic matter in the high-temperature furnace decomposite and carbonize, volatiles discharged with the flue gas. As the glass cloth in the high-temperature furnace through the shorter time, there are still some incomplete carbonization of organic matter is still left on the cloth. Therefore, the high-temperature furnace pre-desizing cloth (also known as “KH cloth”) was dark brown. KH cloth guide roller into the feed section of storage rack, and then sent by the feeding roller into the winding device, winding to the heat treatment with the hole on the steel pipe.

After the warp sizing of the fabric woven into the general organic content of 1.7% to 5.0%, the variety of cloth is very different due to the size and sizing rate. The purpose of continuous thermal desliming is to remove most of the organic matter on the cloth, so that the amount of residual organic matter (referred to as the amount of residual fat) reduced to 0.5%. Continuous heat treatment process is the key to master the treatment of temperature and time, for KH unit, the key is to correctly set and control the temperature and desizing furnace temperature and operating speed. As the heating method, the heating principle and the furnace structure is different, different KH unit set temperature requirements will be different. The same unit with different operating speeds, the furnace temperature setting also need to change. When the speed increases, in order to ensure the desizing effect, the need to properly improve the furnace temperature, but the furnace temperature should not be too high, because the higher the temperature the greater the loss of electronic cloth. In general, the processing temperature of electronic cloth is not higher than 450 ℃ is appropriate, furnace temperature and operating speed setting and adjustment of the target is to achieve the technical requirements of organic residues indicators, while minimizing the loss of strength. The exact amount of residual fat should be sampled and sent to the laboratory for testing. Experienced by KH cloth color of the observation can also be roughly determine the treatment effect.

Continuous heat treatment furnace heating temperature is high, usually used for electric energy, this furnace commonly known as electric furnace. As long as the appropriate resistance elements connect into the power grid, you can convert electrical energy into heat, thereby performing heating. And the electric furnace structure is simple, easy maintenance, temperature control is simple and reliable, and its thermal efficiency is also high, up to 50% to 80% of the electrical parameters of the circuit can be adjusted to control the temperature of the power, therefore, the electric heating is the ideal glass fiber fabric for continuous heat treatment furnace heat source for most of the glass fiber plant used.

Gas, liquefied petroleum gas can also be used as heat treatment furnace heat source, mainly because of its high calorific value, more economical, but their combustion temperature is not easy to control, complex institutions, generally continuous heat treatment furnace does not use gas

Batch heat treatment

Batch heat treatment, also known as thermal desizing, referred to as “BH”, the task is to completely remove the remaining organic material on the cloth, , Electronic cloth residual fat content reached 0.05%, while minimizing the loss of fabric strength.

Batch heat treatment process is that after Pre-desizing the fabric, the wound in the stainless steel tube on the hole, on a dedicated steel shelf and put Into the BH furnace for stew burning.

The residual organic matter on the fabric is decomposed and carbonized in the furnace, and its volatiles are discharged out of the furnace through the recycle gas. The processing time of the fabric in the furnace can be determined according to the variety and specification of the gray fabric and the amount of the organic matter residue after the treatment in the KH furnace. After the set time, BH furnace will automatically stop running. Meantime, you can open the door heat, until the cloth surface temperature dropped to the handle is not hot, you can remove from the shelf, transported to the surface of the chemical treatment furnace to be processed. As the residual organic matter on the fabric was completely decomposed and carbonized in the BH furnace, the surface of the fabric treated by the BH furnace showed a pure white color. The technological requirement of the process is that the temperature curve is set correctly and the treatment time is strictly controlled so that the residual amount of the organic matter in the gray cloth is controlled to be 0.05% or less, and the fabric is ensured to achieve the specified tensile strength.

Batch heat treatment process is the key to master the processing temperature and processing time. For the high-temperature oven, the key is to set the furnace temperature, heating time and holding time, these parameters should be based on the electronic cloth of different specifications, fabric content and KH process conditions, and the structure and heat oven work principle. rule of thumb often set the initial parameters, and then determine the optimum parameters by trial and adjustment. Furnace temperature generally not more than 400 ℃ is appropriate, processing time required 40 ~ 60h. The temperature is too high, the loss of electronic fabric strength is too large, the processing time is too short, the cloth roll may also be internal. Practice that setting the furnace temperature is slightly lower and longer processing time, to ensure the quality of electronic cloth is more favorable, you can achieve low residual fat and retain the effect of high strength.

Batch heat treatment furnace is a closed high-temperature baking furnace, You can not only use liquefied petroleum gas or gas, natural gas as a heat source, also fuel as a heat source. Different heat sources need to be equipped with different combustion devices. However, for the batch heat treatment furnace, because the processing time is longer, heat treatment furnace is fully enclosed, the use of hot air circulation heating type. If the use of electric, power consumption is very powerful and high cost. Wrapped in the steel pipe with a hole on the KH cloth placed in a dedicated steel rack to put BH furnace, filled with a furnace closed the door, the ignition temperature to reach the set temperature and then heat a few 10h.

KH cloth on the residual organic matter in the BH furnace is oxidized, its products free out, in the hot air under the guidance of the discharge from the furnace. When the set time automatically shut down, this time can open the door, to be slightly cool after the take-out cloth frame to complete the batch of thermal desizing process.

Surface chemical treatment

Electronic fabric surface chemical treatment is in the surface treatment unit (FN unit) on the completion of the surface chemical treatment of electronic fabric referred to as FN cloth. Surface chemical treatment unit is composed of multi-unit device composed of continuous processing unit, which is the core part of the processing of liquid immersion device and drying device.

The processing solution impregnation means is movable up and down while the immersion roller is fixed, When the speed of cloth is determined, by adjusting the dipping tank of the upper and lower position and height of the tank to adjust the liquid immersion time. The electronic cloth impregnated with the treating liquid leaves the treating liquid and is then squeezed by a pair of rubber pressing rollers to increase the permeation of the treating liquid, to drive out the bubbles in the cloth, and to remove the excessive treating liquid. Squeeze roller material hardness, higher pressure are also important parameter to determine the content of the treatment agent and impregnation quality electronic cloth. For the General electronic cloth, the content of the treatment liquid on the squeeze roller back cloth is controlled within the range of 20% to 30%.

About 99% of the treatment solution is water, so the squeeze roller leads to the electronic cloth also contains large amounts of water, need to be removed by oven. Oven heating principle and the furnace structure is different from the drying effect is also different, generally the temperature does not exceed 170 ℃ to the principle of the baking cloth after the moisture content of not more than 0.1% for the target adjustment and control. Because the temperature is too high affecting the effect of coupling agent, moisture content is too high will affect the application performance of cloth. Surface chemical treatment of the key quality indicators are organic content. As a result of batch heat treatment of BH cloth still has 0.05% of the following organic residue. Therefore, the FN cloth measured by the general test contains the content of the post-treatment agent and the residual amount of the original organic substance. The FN cloth that has undergone surface chemical treatment should be within the range of 0.05% to 0.25% according to the IPC standard.

Now the world’s electronics industry is developing rapidly, the electronic fabric has also been put forward higher requirements. To meet the new requirements of the electronics industry, electronics manufacturers not only research and development of new coupling agents and additives, and other chemical treatment of new technologies, but also research and development of a number of chemical processing combined with the new treatment methods, Such as high-pressure water jet method. Japan successfully developed this new electronic cloth known as the SP cloth. SP cloth processing principle is the use of high-pressure water jet, so that warp and weft exposed to the cloth part of the fiber evenly spread into flat, also known as the “open fiber” cloth. There is also a physical processing method, the purpose of the processing and the same as the open cloth, the difference is that it uses mechanical scrape method to achieve the effect of open fiber. It is said that this method can achieve the effect similar to the SP cloth, does not require high-pressure water injection system and extrusion drying device can be combined in the surface chemical treatment unit can also be combined in the inspection machine, the processing cost is lower. Further, there is a thermal burn-over method in which the glass cloth is subjected to an over-burning treatment at a temperature higher than the ordinary process or for a longer time in the thermal cleaning process to appropriately reduce the tensile strength of cloth, the cloth brittle, so as to improve the drilling of the cloth processing and improve the quality of the hole wall. After the burning of the glass cloth called cloth or brittle cloth.

Electronic grade fiberglass is an indispensable new engineering material and high-quality structural material for the further development of the electronics industry and scientific and technological progress, so the market prospects will be getting better and better. As an electronic grade fiberglass manufacturer not only to improve the number of electronic-grade glass fiber products, but also to continuously improve product quality, increase product specifications, expand product variety, in order to meet the market’s operational development.