Discussion on influencing factors of utilization ratio of glass fiber infiltrating agent

In recent years, fiber glass strand and its products falling prices, and raw material prices rising, prices had a great influence on the rising cost of energy. How in the presence of these unfavorable factors to reduce costs, improve efficiency becomes the key to glass fiber enterprise survival and development.

Soakage agent cost holds a large proportion in glass fiber production, how to reduce soakage agent consumption in production, improve the utilization efficiency of soakage agent, become the urgent matter. Reduced consumption, the first should be thoroughly analyzes the influential elements of the soakage agent consumption, to adopt technology reform, actively adopt new technology, new technology of saving energy and reducing consumption, radically reduce the consumption of raw materials, in achieve the goal of product quality at the same time, ensure the realization of the cost control target.

The utilization of soakage agent

The concept of utilization

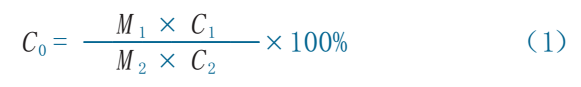

Soakage agent utilization is ratio that soakage agent content coated by glass fiber strand and consume total of soakage agent by producing these strands. Form (1) said:

In the form

C0 —the utilization of soakage agent,%;

C1 —the strand combustible content,%;

C2 —the solid content of water soakage agent,%;

M1 —the strand weight,kg;

M2 —weight for water soakage agent consumption,kg。

The influencing factors of utilization

In production, there are many factors that can affect water soakage agent consumption, among various factors are inextricably linked. Below factors influence the utilization ratio of soakage agent in production of a detailed analysis.

Production factors

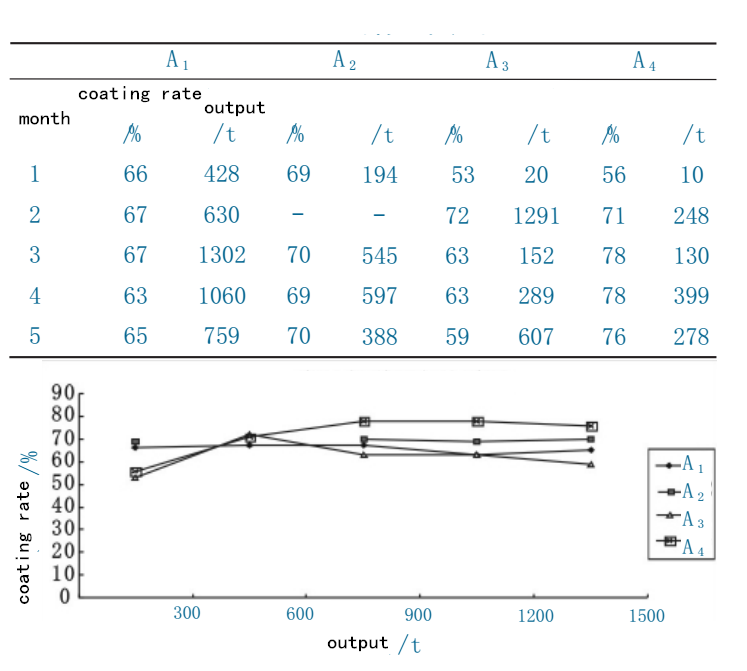

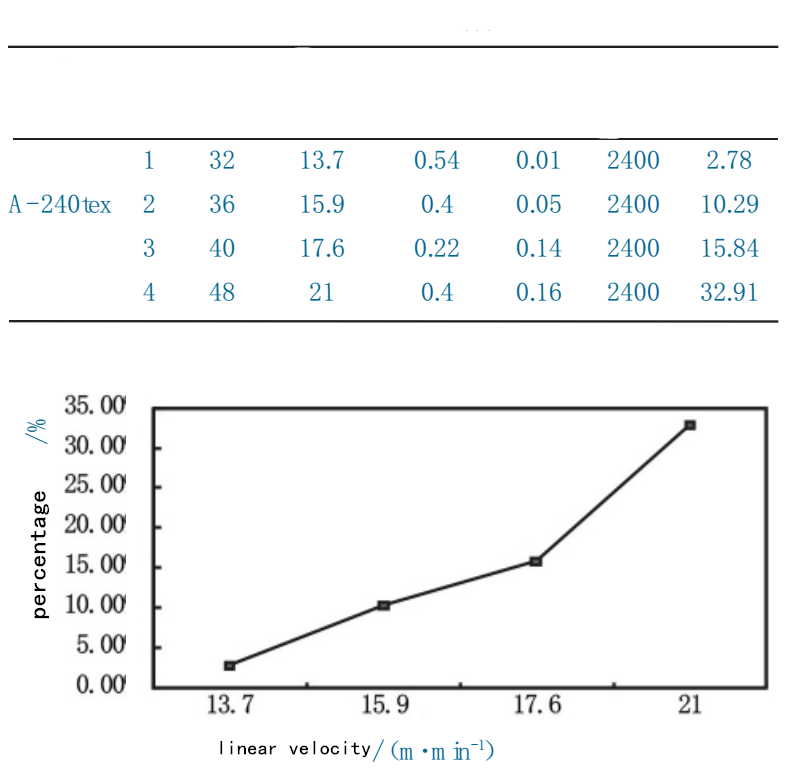

Different and the same variety in different yield and other factors unchanged, under the condition of soakage agent utilization statistics are shown in table 1, the relationship between yield and utilization ratio is shown in figure 1.

Table 1 utilization statistics of soakage agent

Figure 1 relationship between output and utilization

You can see through the table 1 and figure 1, at the time of production is not particularly small, utilization rate basically stable, but the yield is too small, soakage agent utilization rate is relatively low, this is because the first production, soakage agent in circulating water system loss relative to the total soakage agent consumption is too large, lead to formula in M2 artificially high, cause soakage agent utilization is too low.

Strand combustible content and factor of soakage water solid content

Both strand combustible content and the solid content of water soakage agent has a very close relationship with Soakage agent utilization, a separate analysis could not realize, so the unified consideration of both.

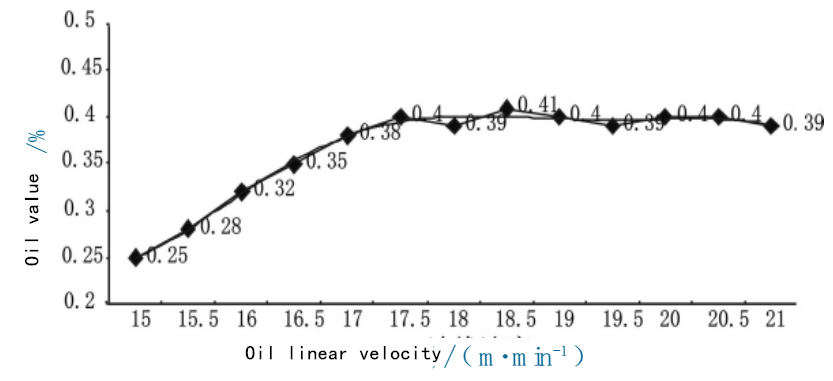

When a certain solid content, in order to ensure sufficient combustible content in the coating rate, under the condition of the same homework (test is to use oil speed to achieve improved), coated strand on the number of soakage agent content after reaching a certain value, the strand combustible content will have a limit value, at this time no matter what the strand wire coating soakage agent content increase, combustible content is close to the limit, as shown in figure 2.

Figure 2 oil change curve

Visible, the demand of the strand combustible content is higher, but solid content is low, so, in order to ensure that the strand combustible content in the qualified range, only improve the oil linear velocity, and thus brings more problems, the soakage agent utilization reduce, under the condition of limit utilization rate is almost zero.

Strand can touch of the soakage agent + water quantity is certain, when stained with overburden amount reach saturation, more stained by strand agent will be replaced by water, resulting in the loss of soakage agents, reducing the efficiency of soakage agent.

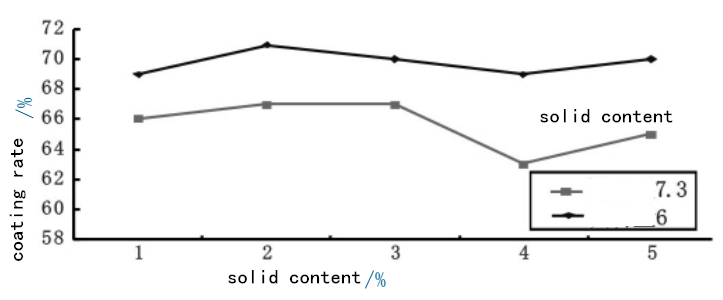

When solids have been able to meet the requirements of the strand combustible content, while the strand combustible content in certain, the relationship between how much of solid content and the utilization of discretion is shown in figure 3.

Figure 3 the relationship between solid content and utilization

You can see from figure 3, solid content is low, utilization rate is higher. Therefore, strand combustible content and solid content must be in appropriate range, soakage agent utilization can reach ideal level.

Weight for water infiltration agent consumption

This is the result of joint action of many factors, in production, combustible content, solid content under the condition of relatively stable, glass fiber production field control level and the waste water soakage agent determines the soakage water consumption of the weight of high or low, relatively stable production and the sustainability of the single variety, to reduce the waste of water soakage agent weight has obvious effect.

Greased speed range of manufacturing has a large span (the same variety, same flow, oil frequency can differ 9), but oil frequency reach a certain extent, oil will not significantly change, frequency of oil gap among different cameras. Spray quantity is big, the position of the strand bunches drip down, in the drawing line the agent thrown around a lot, you can see through the table 2 and figure 4 wire drawing parameters right or not affect soakage agent consumption.

Table 2 Drawing on soakage agent consumption statistics

Figure 4 loss ratio

To improve these problems, the consumption of water soakage agent will reduce a lot, to improve the utilization rate of soakage agent has very great help.

Conclusion

To sum up, the utilization ratio of soakage agent is the result of the interaction of various factors, the stability of the production is the basis of the various discussions, and production control level also plays a very important role in it. Strand combustible content and solid content of high or low must be in the proper range, within the scope of the soakage agent utilization can reach ideal level.