Roller opening technology

Working principle

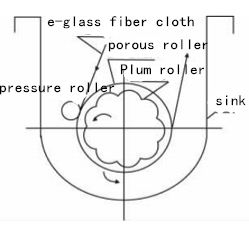

The e-glass fiber cloth is wrapped on the perforated roller by the front and rear tension rollers, and the plum roller concentric with the perforated roller is driven by the variable frequency motor. The device is placed in a water filled water tank. when equipment operation, Plum roller vibration generated by the water roller through the porous roller to the fiberglass cloth, so that the e-glass fiber cloth warp and weft fibers to disperse, to achieve the purpose of opening.

Figure 1 roller open fiber works

Theoretical analysis

According to the forced vibration system with damping formula

In the formula:

y———Vibration displacement,mm;

A———amplitude,mm;

ω———Angular velocity,rad /s;

t———Phase angle, mm /s

u———Vibration velocity,mm /s

According to the vibration mechanical wave principle

![]()

In the formula:

I———The average energy density is the wave vibration intensity,w /m2;

ρ———Medium density,g /cm3

Substituting (1) into (2) yields

![]()

From (3), the vibration intensity of the wave is proportional to the cube of the rotational speed and amplitude. Because the effect of opening the fiber is proportional to the vibration intensity of the wave, that is to say, increasing the rotational speed, increasing the petal number of the plum roller or increasing the petal will increase the vibration intensity of the wave. But the speed and the number of petals and the size of the increase to consider the e-glass fiber cloth fiber strength, that is, open fiber can not cause hairiness and weft oblique, hairiness and latitude to ensure control in the allowable range, select the appropriate speed and plum roller.

Open process

Open the process of fiber should pay attention to the following questions:

The speed of the perforated roller driven by the servo motor (see Fig. 1) should be synchronized with the master. To ensure fabric tension, the servo motor speed can be set on the touch screen by the manual adjustment.

In order to prevent the water wave oscillation so that the cloth from the porous roller, you can add a roller in the roller (see Figure 1), the gap between the porous roller and the pressure roller can be adjustable.

In consideration of the e-glass fiber cloth opening process with hairiness and weft obliquity, we adopt thirty-two petals roller, and then according to the variety of cloth and yarn source, select the plum roller speed, usually thin cloth is 200 ~ 400 r / m, thick cloth is 400 ~ 500 r / m.

Open fiber effect

The air permeability of the e-glass fiber cloth directly reflects the effect of the fiber opening. The air permeability of the unopened 7628 e-glass fiber cloth is generally 6-8 cm / s, and the air permeability of the 7628 e-glass fiber cloth after the roller is opened is less than 3 cm / s . Respectively, take the width of e-glass fiber cloth on the left, middle and right part of the three samples measured permeability, measured in Table 1.

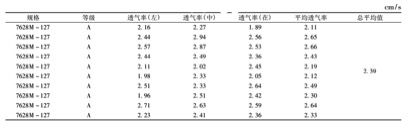

Table 1 the air permeability after the opening of the fiberglass roller cloth