Use of e-glass fiber cloth Flattening Techniques

Electronic Fiberglass Cloth (hereinafter referred to as e-glass fiber cloth ) usually made up of warp and weft yarns composed of a plurality of filaments.To meet the rapid development of the electronics industry, CCL enterprises require e-glass fiber cloth warp and weft single fiber can be spread evenly, forming flat, known as the “open fiber.”through the opening treatment e-glass fiber cloth can improve the resin impregnation, thereby improving the peel strength of copper clad laminate and circuit board drilling processability. The general opening of e-glass fiber cloth usually using three ways for fiber open ,such as high-pressure spunlaced fiber, roller open and high-pressure water spray,As the former huge investment, usually e-glass fiber cloth production plant using the latter two open fiber way. Roller opening technology and High Pressure Water Spraying Technology.

Contrast of Two Kinds of Opening

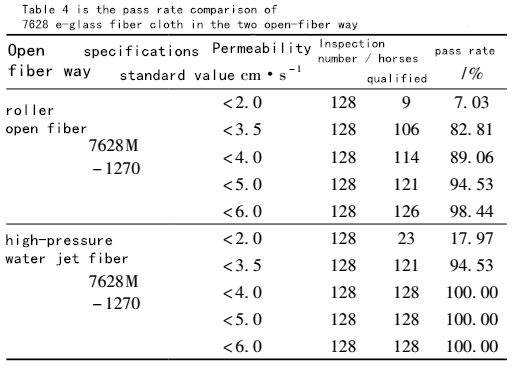

Roll open and high-pressure water spray fiber effect comparison in Table 4.

Table 4 is the pass rate comparison of 7628 e-glass fiber cloth in the two open-fiber way.

seen from Table 4, under the same air permeability standards, the high-pressure water-jetting of the e-glass fiber cloth,the greater the pass rate than the open-roll, so under the correct choice of the nozzle type, jet height and the injection pressure, the high pressure Water sprayed fiber way has a better opening fiber effect than the open-roll fiber.

Conclusion

The flattening(open fiber) of e-glass fiber cloth has become a must be in production process . In this paper, through the comparison of the principle and application about the two methods of open fiber analysis and analysis of the fiber technology to improve, I believe that high-pressure water spray open fiber way has a better effect than the open-fiber roller, which provides a more comprehensive guide on improve the e-glass fiber cloth opening technology.